Application of Pure Aluminium Foam

Aluminum foam is suitable for high-speed rail, subway, concert hall,

cinema, recording studio, studio, song and dance hall, gymnasium, subway

station, waiting hall, waiting room, hotel lobby, large shopping malls,

exhibition hall, office hall, news room, computer room

Such as decoration materials, sound barrier sound absorption materials,

high fire grade materials; Environmental protection new materials

First, the main characteristics of aluminum foam sound absorption board:

1, the new foam aluminum plate, sound absorption performance is good,

stable acoustic performance, no pollution, light weight, beautiful, fire

prevention, not afraid of water, good physical properties, easy

processing, with it made of various forms of sound absorption body,

muffler, sound insulation structure, sound barrier,

Silencer room, sound insulation cover, etc., can directly face the noise

source, do not need any protective panel and other sound absorbing

filler.

2, with good acoustic performance: average sound absorption coefficient

≥0.60 (125-4000Hz frequency range, Measured by tongji University

Acoustics); At the same time, it has good acoustic performance that the

sound absorption performance does not change after spraying water and

ash.

3. The foam aluminum plate is made of aluminum alloy, which can be

recycled after being damaged. It is a new green environmental protection

product that does not cause secondary pollution to the environment at

present.

4. Aluminum foam plate is the forefront and replacement product of

non-fibrous materials at present. It will not become dust after aging

and cause secondary pollution to the atmospheric environment like glass

fiber, mineral wool, rock wool and other environments caused by sun and

rain and high temperature.

5, with metal aluminum corresponding fire incombustible, weather

resistance, corrosion resistance, wind, rain, sun, is A class A

non-combustible products.

6, can be coated with different colors of coating, beautiful, coating

after several dilute spray, drying and other processes, so even in the

wind and sun conditions, will not fade.

7, with good electromagnetic shielding performance.

8, foam aluminum sound absorption plate can be sawed, can be arbitrary

bonding, riveting, plug, easy installation.

9, foam aluminum plate can be made into various forms of sound

absorption body, but also can be combined into various forms of sound

absorption, sound insulation body.

10, the surface is easy to clean, convenient maintenance.

Two, the scope of application of aluminum foam sound absorption board

Used in concert hall, cinema, recording studio, studio, dance hall,

gymnasium, subway station, waiting hall, waiting room, hotel lobby,

large shopping mall, exhibition hall, office hall, news room, computer

room and other places to control the sound

Effect of reverberation time.

For pipe muffler, muffler elbow, static pressure box, especially

suitable for clean workshop, food production workshop, pharmaceutical

factory, precision instrument manufacturing workshop, laboratory, ward,

operating room, dining room, ship engine room, auxiliary engine room,

cabin and other places

The air conditioning and ventilation equipment play a noise-reducing

role.

In urban light rail, elevated road, traffic trunk road, highway,

railway, overpass, cooling tower, open-air high-voltage substation,

concrete mixing field and other places play the role of sound absorption

barrier.

In diesel engine, generator, motor, internal combustion engine, freezer,

air compressor, aircraft, train, automobile, ship, boiler, forging

hammer equipment, fan and other equipment, can be sound absorption,

sound insulation, muffler effect.

3. Performance test results of aluminum foam sound absorbing board

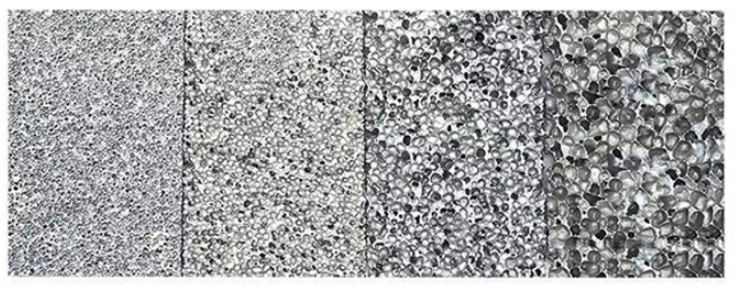

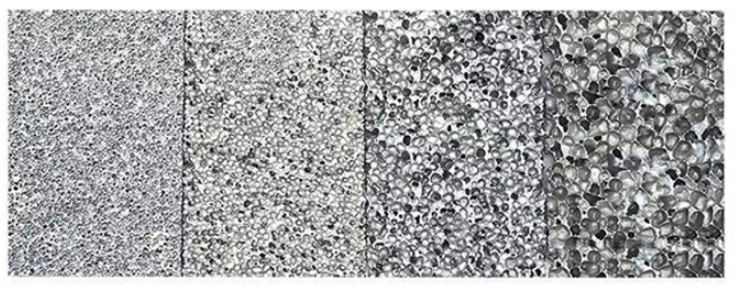

Pore characteristics and volume density

Main aperture: 0.9mm, 1.6mm, 2.5mm three specifications, common

specification is 1.6mm aperture.

Porosity: 60-80% (68-78% at 1.6mm aperture)

Through-hole rate: 85-95% (90-95% for 1.6mm aperture)

Volume density: 0.5-1.10g/cm3 (0.60-0.85g/cm3 for 1.6mm aperture)

Flammability: determined according to GB/T5464

The combustion performance of the sound-absorbing board conforms to the

provisions of GB8624 non-combustible material (CLASS A) : it belongs to

non-combustible material.

Hygroscopic performance: determined according to GB5480.7 (

Mass hygroscopicity W1 < 0.1%

Volume hygroscopicity W2 < 0.1%

Mechanical properties: refer to GB/T1039-1040 determination

Compressive strength δ C: 8.61Mpa (at 10% compression)

Bending strength δ W: 8.06mpa

Tensile strength δ B: 3.41Mpa

Aging resistance: determined according to GB/T14522 (Shanghai Institute

of Construction Science inspection Station)

After 250 hours of testing, there is no discoloration, no shedding and

no aging phenomenon

Electromagnetic shielding: according to GB/12190 and SJ20524

determination

Shielding efficiency 40-55dB (80khz-1.5ghz frequency range measurement)

Sound absorption performance: according to GBJ47 and GBJ88 measurement

Average sound absorption coefficient (measured in frequency range

125-4000Hz)

Noise reduction coefficient NRC 0.64 (250-2000Hz frequency range

determination)

Sound insulation performance: measured according to GBJ75

Air acoustic meter weight sound insulation Rw 28.0dB (sound insulation

index LA)

Average sound insulation Ra 24.5dB (125-4000Hz frequency range

measurement)

Other metal foam

nickel foam

titanium foam

iron foam

aluminum foam

copper foam

cobalt foam

silver foam

Zinc foam

carbon foam

Nickel

Molybdenum

Iron Nickel

Cobalt

Nickel

Stainless

steel

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Aluminum foam is suitable for high-speed rail, subway, concert hall,

cinema, recording studio, studio, song and dance hall, gymnasium, subway

station, waiting hall, waiting room, hotel lobby, large shopping malls,

exhibition hall, office hall, news room, computer room

Such as decoration materials, sound barrier sound absorption materials,

high fire grade materials; Environmental protection new materials

First, the main characteristics of aluminum foam sound absorption board:

1, the new foam aluminum plate, sound absorption performance is good,

stable acoustic performance, no pollution, light weight, beautiful, fire

prevention, not afraid of water, good physical properties, easy

processing, with it made of various forms of sound absorption body,

muffler, sound insulation structure, sound barrier,

Silencer room, sound insulation cover, etc., can directly face the noise

source, do not need any protective panel and other sound absorbing

filler.

2, with good acoustic performance: average sound absorption coefficient

≥0.60 (125-4000Hz frequency range, Measured by tongji University

Acoustics); At the same time, it has good acoustic performance that the

sound absorption performance does not change after spraying water and

ash.

3. The foam aluminum plate is made of aluminum alloy, which can be

recycled after being damaged. It is a new green environmental protection

product that does not cause secondary pollution to the environment at

present.

4. Aluminum foam plate is the forefront and replacement product of

non-fibrous materials at present. It will not become dust after aging

and cause secondary pollution to the atmospheric environment like glass

fiber, mineral wool, rock wool and other environments caused by sun and

rain and high temperature.

5, with metal aluminum corresponding fire incombustible, weather

resistance, corrosion resistance, wind, rain, sun, is A class A

non-combustible products.

6, can be coated with different colors of coating, beautiful, coating

after several dilute spray, drying and other processes, so even in the

wind and sun conditions, will not fade.

7, with good electromagnetic shielding performance.

8, foam aluminum sound absorption plate can be sawed, can be arbitrary

bonding, riveting, plug, easy installation.

9, foam aluminum plate can be made into various forms of sound

absorption body, but also can be combined into various forms of sound

absorption, sound insulation body.

10, the surface is easy to clean, convenient maintenance.

Two, the scope of application of aluminum foam sound absorption board

Used in concert hall, cinema, recording studio, studio, dance hall,

gymnasium, subway station, waiting hall, waiting room, hotel lobby,

large shopping mall, exhibition hall, office hall, news room, computer

room and other places to control the sound

Effect of reverberation time.

For pipe muffler, muffler elbow, static pressure box, especially

suitable for clean workshop, food production workshop, pharmaceutical

factory, precision instrument manufacturing workshop, laboratory, ward,

operating room, dining room, ship engine room, auxiliary engine room,

cabin and other places

The air conditioning and ventilation equipment play a noise-reducing

role.

In urban light rail, elevated road, traffic trunk road, highway,

railway, overpass, cooling tower, open-air high-voltage substation,

concrete mixing field and other places play the role of sound absorption

barrier.

In diesel engine, generator, motor, internal combustion engine, freezer,

air compressor, aircraft, train, automobile, ship, boiler, forging

hammer equipment, fan and other equipment, can be sound absorption,

sound insulation, muffler effect.

3. Performance test results of aluminum foam sound absorbing board

Pore characteristics and volume density

Main aperture: 0.9mm, 1.6mm, 2.5mm three specifications, common

specification is 1.6mm aperture.

Porosity: 60-80% (68-78% at 1.6mm aperture)

Through-hole rate: 85-95% (90-95% for 1.6mm aperture)

Volume density: 0.5-1.10g/cm3 (0.60-0.85g/cm3 for 1.6mm aperture)

Flammability: determined according to GB/T5464

The combustion performance of the sound-absorbing board conforms to the

provisions of GB8624 non-combustible material (CLASS A) : it belongs to

non-combustible material.

Hygroscopic performance: determined according to GB5480.7 (

Mass hygroscopicity W1 < 0.1%

Volume hygroscopicity W2 < 0.1%

Mechanical properties: refer to GB/T1039-1040 determination

Compressive strength δ C: 8.61Mpa (at 10% compression)

Bending strength δ W: 8.06mpa

Tensile strength δ B: 3.41Mpa

Aging resistance: determined according to GB/T14522 (Shanghai Institute

of Construction Science inspection Station)

After 250 hours of testing, there is no discoloration, no shedding and

no aging phenomenon

Electromagnetic shielding: according to GB/12190 and SJ20524

determination

Shielding efficiency 40-55dB (80khz-1.5ghz frequency range measurement)

Sound absorption performance: according to GBJ47 and GBJ88 measurement

Average sound absorption coefficient (measured in frequency range

125-4000Hz)

Noise reduction coefficient NRC 0.64 (250-2000Hz frequency range

determination)

Sound insulation performance: measured according to GBJ75

Air acoustic meter weight sound insulation Rw 28.0dB (sound insulation

index LA)

Average sound insulation Ra 24.5dB (125-4000Hz frequency range

measurement)

Other metal foam

| nickel foam | titanium foam | iron foam | aluminum foam | copper foam |

| cobalt foam | silver foam | Zinc foam | carbon foam | Nickel Molybdenum |

| Iron Nickel | Cobalt Nickel | Stainless steel |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

granules | 6mm-13mm | 99.99% | Details | |||