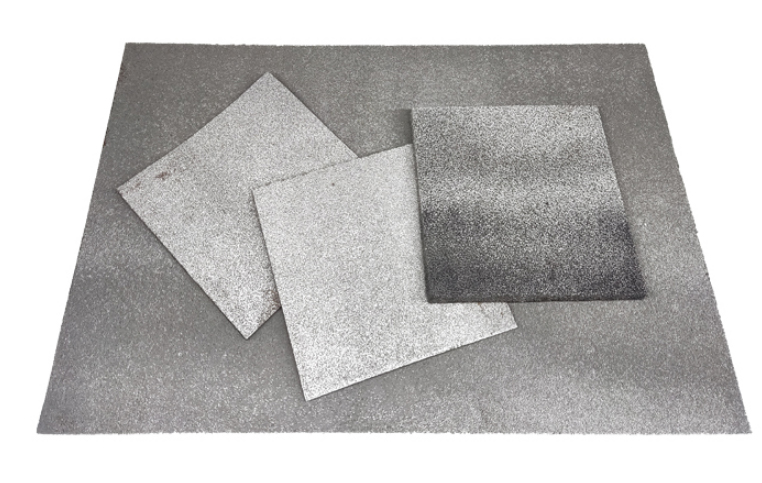

High purity Iron Foam 99.9 %

hnical parameters of iron foam:

Thickness: 1.0mm 1.5mm 2.0mm 3mm 5mm 10mm 15mm

Aperture: 95 ppi (0.2-10 mm)

Porosity: 60-98%

Through-hole ratio: ≥98

Volume density: > 0.1g/cm3

PPi(number of holes per inch) : 5-130 Maximum geometry: 500 x 1000mm

(can also be customized)

Tensile strength: 8-50mpa

Compressive strength: ≥250KPa (compressed to 50% pressure value)

Mechanical strength: 2-7mpa High temperature: > 300℃ Heat transfer

coefficient: > 3W /(M2K)

The electrode material used as alkaline rechargeable battery is the most

promising electrode material for battery manufacturers to replace nickel

foam and reduce production cost.

.

Other metal foam

nickel foam

titanium foam

iron foam

aluminum foam

copper foam

cobalt foam

silver foam

Zinc foam

carbon foam

Nickel

Molybdenum

Iron Nickel

Cobalt

Nickel

Stainless

steel

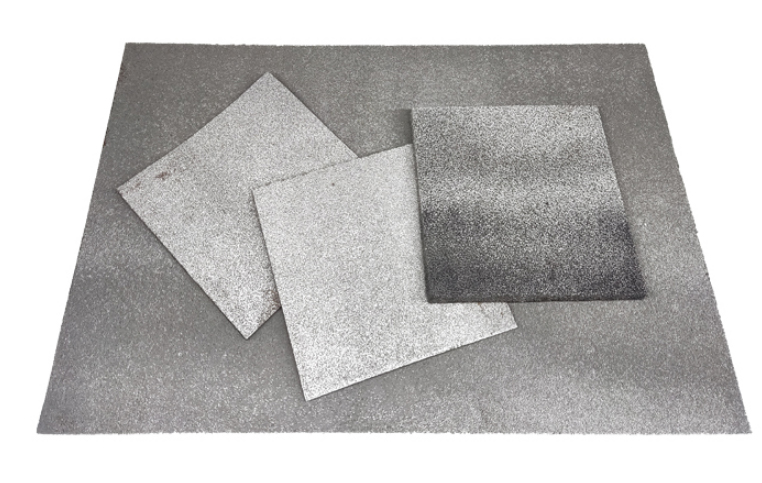

hnical parameters of iron foam:

Thickness: 1.0mm 1.5mm 2.0mm 3mm 5mm 10mm 15mm

Aperture: 95 ppi (0.2-10 mm)

Porosity: 60-98%

Through-hole ratio: ≥98

Volume density: > 0.1g/cm3

PPi(number of holes per inch) : 5-130 Maximum geometry: 500 x 1000mm

(can also be customized)

Tensile strength: 8-50mpa

Compressive strength: ≥250KPa (compressed to 50% pressure value)

Mechanical strength: 2-7mpa High temperature: > 300℃ Heat transfer

coefficient: > 3W /(M2K)

The electrode material used as alkaline rechargeable battery is the most

promising electrode material for battery manufacturers to replace nickel

foam and reduce production cost.

.

Other metal foam

| nickel foam | titanium foam | iron foam | aluminum foam | copper foam |

| cobalt foam | silver foam | Zinc foam | carbon foam | Nickel Molybdenum |

| Iron Nickel | Cobalt Nickel | Stainless steel |