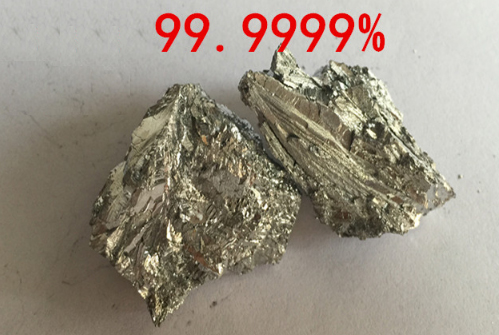

99.99% and 99.999% and 99.9999% Antimony Pure Metal Ingot

Antimony is a semimetal in terms of its properties, that is, it

exhibits metallic and non-metallic properties. Semi-metals also include

silicon, boron, germanium, arsenic and tellurium. Antimony as a simple

substance is known in several allotropic modifications, of which the

most stable is crystalline - brittle silvery-white crystals with a

metallic luster. The density of this antimony is 6.68 kg / dm^3, the

melting point is 630.5 ° C, and the boiling point is 1635 ° C. Other

modifications are unstable under standard conditions and easily

(sometimes with an explosion) transform into crystalline antimony.

Liquid antimony expands during solidification (bismuth and gallium have

the same property), while ingots are easy to split, antimony practically

does not lend itself to forging. According to its magnetic properties,

it belongs to diamagnets.

Antimony is increasingly used in the semiconductor industry in the

production of diodes and infrared detectors, as well as in the

production of thermoelectric materials. For example, it can be used as a

dopant for semiconductors (electron donor): the addition of antimony to

germanium gives it certain semiconducting properties. Some antimonides

(aluminum, gallium, indium) also belong to semiconductor materials.

Antimony telluride Sb2Te3 is used as a component of thermoelectric

alloys with bismuth telluride. These areas also require a high purity of

antimony, in some cases a purity of 6N (99.9999%) is required

Antimony is a part of a large number of industrial alloys (more than two

hundred are known) as an alloying additive. Thus, the introduction of

antimony into the alloy increases its hardness, wear resistance, and

oxidation resistance. The most common are the following: bearing metals,

gartble, printing metal.

Bearing metals are alloys of antimony with lead, tin and copper,

sometimes also with bismuth and zinc. Babbits, the most common of them,

contain from 4% to 15% antimony and are intended for use as a layer,

cast or sprayed on the shell of the plain bearing shell. Thus, the field

of application of bearing metals is very wide: the automotive industry,

machine tools, and railroad transport.

The property of antimony to expand from a liquid to a solid state is

used in printing metal (mainly composed of antimony, lead and tin): the

addition of antimony makes it possible to obtain clear prints, as well

as to increase impact resistance, wear resistance and hardness. Lead

with the addition of antimony is used to make bullets and shrapnel,

battery plates (antimony content 5-15%).

Other areas of application of antimony and its compounds: production of

ceramics, dyes, special glasses (oxides, sulfides and antimony

trichloride), refractory materials (antimony (III) oxide), medicine and

cosmetics, production of matches (antimony (III) sulfide). Antimony

petafluoride in a mixture with hydrogen fluoride and / or other strong

acids is used to create a super acidic medium in fine organic synthesis

and research.

Antimony is moderately toxic, while trivalent antimony compounds are

more dangerous. Poisoning can be caused by dust or vapors of compounds,

the maximum concentration limit of aerosol in the air of the working

area is 0.0005 mg / l.

.

99.9999%, (6N)Antimony Pieces

99.999%, (5N)Antimony

Pieces

99.99%, (4N)Antimony

Antimony is a semimetal in terms of its properties, that is, it

exhibits metallic and non-metallic properties. Semi-metals also include

silicon, boron, germanium, arsenic and tellurium. Antimony as a simple

substance is known in several allotropic modifications, of which the

most stable is crystalline - brittle silvery-white crystals with a

metallic luster. The density of this antimony is 6.68 kg / dm^3, the

melting point is 630.5 ° C, and the boiling point is 1635 ° C. Other

modifications are unstable under standard conditions and easily

(sometimes with an explosion) transform into crystalline antimony.

Liquid antimony expands during solidification (bismuth and gallium have

the same property), while ingots are easy to split, antimony practically

does not lend itself to forging. According to its magnetic properties,

it belongs to diamagnets.

Antimony is increasingly used in the semiconductor industry in the

production of diodes and infrared detectors, as well as in the

production of thermoelectric materials. For example, it can be used as a

dopant for semiconductors (electron donor): the addition of antimony to

germanium gives it certain semiconducting properties. Some antimonides

(aluminum, gallium, indium) also belong to semiconductor materials.

Antimony telluride Sb2Te3 is used as a component of thermoelectric

alloys with bismuth telluride. These areas also require a high purity of

antimony, in some cases a purity of 6N (99.9999%) is required

Antimony is a part of a large number of industrial alloys (more than two

hundred are known) as an alloying additive. Thus, the introduction of

antimony into the alloy increases its hardness, wear resistance, and

oxidation resistance. The most common are the following: bearing metals,

gartble, printing metal.

Bearing metals are alloys of antimony with lead, tin and copper,

sometimes also with bismuth and zinc. Babbits, the most common of them,

contain from 4% to 15% antimony and are intended for use as a layer,

cast or sprayed on the shell of the plain bearing shell. Thus, the field

of application of bearing metals is very wide: the automotive industry,

machine tools, and railroad transport.

The property of antimony to expand from a liquid to a solid state is

used in printing metal (mainly composed of antimony, lead and tin): the

addition of antimony makes it possible to obtain clear prints, as well

as to increase impact resistance, wear resistance and hardness. Lead

with the addition of antimony is used to make bullets and shrapnel,

battery plates (antimony content 5-15%).

Other areas of application of antimony and its compounds: production of

ceramics, dyes, special glasses (oxides, sulfides and antimony

trichloride), refractory materials (antimony (III) oxide), medicine and

cosmetics, production of matches (antimony (III) sulfide). Antimony

petafluoride in a mixture with hydrogen fluoride and / or other strong

acids is used to create a super acidic medium in fine organic synthesis

and research.

Antimony is moderately toxic, while trivalent antimony compounds are

more dangerous. Poisoning can be caused by dust or vapors of compounds,

the maximum concentration limit of aerosol in the air of the working

area is 0.0005 mg / l.

.

|

|

|

|

| 99.9999%, (6N)Antimony Pieces | 99.999%, (5N)Antimony Pieces | 99.99%, (4N)Antimony |