99.99% Zirconium Metal

Zirconium is a shiny

gray-white metal similar to the other elements in group 4 of the

Periodic Table: titanium and hafnium.

Chemical properties

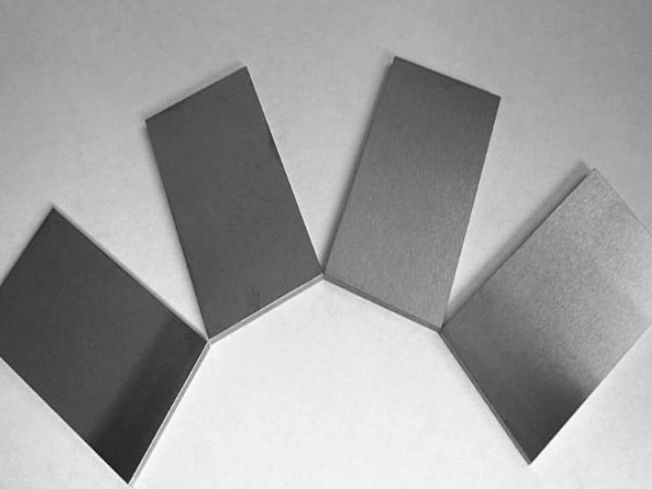

Compact zirconium

Zirconium metal is steel gray and is in pure form a soft and malleable

metal with a high melting point (2125 oC). The metal can be easily drawn

into thin threads and rolled into foils. Up to 863 ° C, the crystal

structure of zirconium metal is hexagonal densest spherical packing.

Above that temperature, the structure is less densely packed (cubic

room-centered).

The metal can dissolve significant amounts of oxygen (up to 30 atomic

percent), nitrogen and hydrogen, and small amounts of these make the

metal more brittle.

Zirconium metal is resistant to air at normal temperatures as it is

covered by a thin layer of oxide (such as aluminum). Only at

temperatures above approx. At 400 ° C, a rapidly increasing oxidation of

the metal is obtained with the formation of an oxide shell of zirconia,

ZrO2, at the same time as oxygen is dissolved in the metal. This makes

zirconium metal unsuitable as a high temperature material.

The metal is very corrosion resistant below 400 oC. It is not attacked

by water, dilute hydrochloric acid and sulfuric acid, phosphoric acid

and organic acids, lye and other. It also works well against molten

alkalis. Zirconium reacts at higher temperatures with the halogens (for

example chlorine), sulfur, carbon, silicon and others with the formation

of halides, sulphides, carbides and silicides.

In their chemical compounds, zirconium has oxidation numbers –II, 0, I,

II, III and IV. The latter is the most common and stable under normal

conditions.

Zirconium powder

In powder or as a porous sponge, the surface area is large, and the

metal is therefore easily ignited in air already at about 200 ° C,

possibly at a lower temperature by rubbing or discharging static

electricity. It must therefore be treated carefully and stored under

argon, in methanol and other. Because the powder reacts with both water

vapor and carbon dioxide, the ignited powder must be extinguished by

covering with dry sand or salt.

Zirconium has a very low impact cross-section for thermal neutrons

(0.184 children), and zirconium is therefore used as an encapsulation

material for fuel elements in nuclear power plants. The effect cross

section is much larger for hafnium (104 children), so the metal used for

fuel elements must not contain more than 0.01% hafnium. (Hafnium is used

instead in the form of rods to control the neutron flux in the nuclear

power plant.) The two elements are separated by different methods, where

extraction with organic solvents is the most common.

Manufacturing

Zirconium-containing sand is concentrated and then melted with coke in

electric arc furnaces at about 3500 ° C. This forms zirconium carbide

and zirconium carbide nitride. After crushing, these are converted by

treatment with chlorine gas to zirconium tetrachloride. .

Reduce the zirconium tetrachloride with magnesium (possibly together

with sodium) in the absence of air (oxygen and nitrogen) in the curling

process: ZrCl4 (g) + 2Mg (s) → Zr (s) + 2MgCl2 (s). The magnesium

chloride and residues of magnesium metal are removed by distillation in

vacuo and the residue becomes zirconium metal in a sponge-like form.

This is melted by arc or electron beam melting in vacuo. Metal that is

free of oxygen and nitrogen is produced by thermal decomposition of

zirconium tetraiodide, ZrI4, according to the van Arkel-de Boer method

(see Anton Eduard van Arkel).

Use

Zirconium is used as an alloy additive to many metals and alloys such as

steel, magnesium and aluminum. Magnesium – zinc – zirconium alloys are

distinguished by high mechanical strength and low weight and are used in

the aerospace industry, among other places. The metal is also used as a

deoxidizing agent, but then in the form of ferrozirconium, ferrosilicon

zirconium and other.

About 90% of the zirconium metal produced in the world is used for

capsules for fuel elements (of uranium dioxide, UO2) in nuclear

reactors, then in the form of an alloy (zircalloy). This use is due to

the good corrosion of the metal

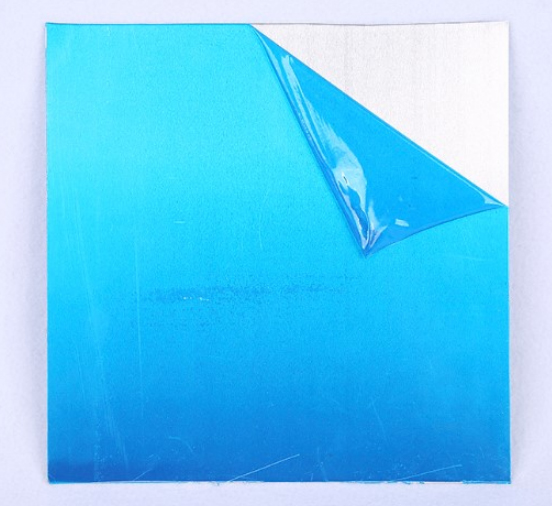

99.99%, (4N)Zr Sheet

99.99%, (4N)Zr Foil

.

Zirconium is a shiny

gray-white metal similar to the other elements in group 4 of the

Periodic Table: titanium and hafnium.

Chemical properties

Compact zirconium

Zirconium metal is steel gray and is in pure form a soft and malleable

metal with a high melting point (2125 oC). The metal can be easily drawn

into thin threads and rolled into foils. Up to 863 ° C, the crystal

structure of zirconium metal is hexagonal densest spherical packing.

Above that temperature, the structure is less densely packed (cubic

room-centered).

The metal can dissolve significant amounts of oxygen (up to 30 atomic

percent), nitrogen and hydrogen, and small amounts of these make the

metal more brittle.

Zirconium metal is resistant to air at normal temperatures as it is

covered by a thin layer of oxide (such as aluminum). Only at

temperatures above approx. At 400 ° C, a rapidly increasing oxidation of

the metal is obtained with the formation of an oxide shell of zirconia,

ZrO2, at the same time as oxygen is dissolved in the metal. This makes

zirconium metal unsuitable as a high temperature material.

The metal is very corrosion resistant below 400 oC. It is not attacked

by water, dilute hydrochloric acid and sulfuric acid, phosphoric acid

and organic acids, lye and other. It also works well against molten

alkalis. Zirconium reacts at higher temperatures with the halogens (for

example chlorine), sulfur, carbon, silicon and others with the formation

of halides, sulphides, carbides and silicides.

In their chemical compounds, zirconium has oxidation numbers –II, 0, I,

II, III and IV. The latter is the most common and stable under normal

conditions.

Zirconium powder

In powder or as a porous sponge, the surface area is large, and the

metal is therefore easily ignited in air already at about 200 ° C,

possibly at a lower temperature by rubbing or discharging static

electricity. It must therefore be treated carefully and stored under

argon, in methanol and other. Because the powder reacts with both water

vapor and carbon dioxide, the ignited powder must be extinguished by

covering with dry sand or salt.

Zirconium has a very low impact cross-section for thermal neutrons

(0.184 children), and zirconium is therefore used as an encapsulation

material for fuel elements in nuclear power plants. The effect cross

section is much larger for hafnium (104 children), so the metal used for

fuel elements must not contain more than 0.01% hafnium. (Hafnium is used

instead in the form of rods to control the neutron flux in the nuclear

power plant.) The two elements are separated by different methods, where

extraction with organic solvents is the most common.

Manufacturing

Zirconium-containing sand is concentrated and then melted with coke in

electric arc furnaces at about 3500 ° C. This forms zirconium carbide

and zirconium carbide nitride. After crushing, these are converted by

treatment with chlorine gas to zirconium tetrachloride. .

Reduce the zirconium tetrachloride with magnesium (possibly together

with sodium) in the absence of air (oxygen and nitrogen) in the curling

process: ZrCl4 (g) + 2Mg (s) → Zr (s) + 2MgCl2 (s). The magnesium

chloride and residues of magnesium metal are removed by distillation in

vacuo and the residue becomes zirconium metal in a sponge-like form.

This is melted by arc or electron beam melting in vacuo. Metal that is

free of oxygen and nitrogen is produced by thermal decomposition of

zirconium tetraiodide, ZrI4, according to the van Arkel-de Boer method

(see Anton Eduard van Arkel).

Use

Zirconium is used as an alloy additive to many metals and alloys such as

steel, magnesium and aluminum. Magnesium – zinc – zirconium alloys are

distinguished by high mechanical strength and low weight and are used in

the aerospace industry, among other places. The metal is also used as a

deoxidizing agent, but then in the form of ferrozirconium, ferrosilicon

zirconium and other.

About 90% of the zirconium metal produced in the world is used for

capsules for fuel elements (of uranium dioxide, UO2) in nuclear

reactors, then in the form of an alloy (zircalloy). This use is due to

the good corrosion of the metal

|

|

|

|

| 99.99%, (4N)Zr Sheet | 99.99%, (4N)Zr Foil |

.