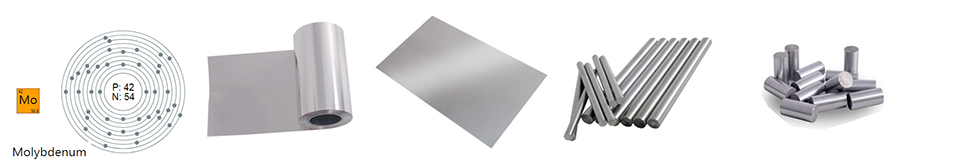

Pure molybdenum product

Molybdenum foil is a high-tech product that combines the properties of

powerful electrical conductivity, thermal conductivity and

refractoriness of the source metal with the physical flexibility of a

thin sheet. Wrap this foil carefully, because molybdenum does not show

such flexibility as, for example, aluminum, although it has great

tensile strength.

Molybdenum foil is used to create the best fire-resistant and

heat-resistant systems. In combination with mineral wool, you can

achieve unique characteristics of thermal insulation. If you wrap pipes

with such foil, then the heat transfer can grow up to 1.8 times. This

allows you to create highly efficient cooling and heating systems. In

combination with molybdenum pipes, foil from this metal is not used.

Molybdenum foil has an extremely low coefficient of thermal expansion

and is resistant to corrosive acid and alkaline environments. Due to

this, the thinnest molybdenum tapes are widely used in the aerospace

industry and radio engineering, as well as in the nuclear and chemical

industries.

The price of molybdenum foil is usually set per roll, but in large

batches a purchase by weight is possible. .

;

.

molybdenum

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

Molybdenum foil is a high-tech product that combines the properties of

powerful electrical conductivity, thermal conductivity and

refractoriness of the source metal with the physical flexibility of a

thin sheet. Wrap this foil carefully, because molybdenum does not show

such flexibility as, for example, aluminum, although it has great

tensile strength.

Molybdenum foil is used to create the best fire-resistant and

heat-resistant systems. In combination with mineral wool, you can

achieve unique characteristics of thermal insulation. If you wrap pipes

with such foil, then the heat transfer can grow up to 1.8 times. This

allows you to create highly efficient cooling and heating systems. In

combination with molybdenum pipes, foil from this metal is not used.

Molybdenum foil has an extremely low coefficient of thermal expansion

and is resistant to corrosive acid and alkaline environments. Due to

this, the thinnest molybdenum tapes are widely used in the aerospace

industry and radio engineering, as well as in the nuclear and chemical

industries.

The price of molybdenum foil is usually set per roll, but in large

batches a purchase by weight is possible. .

;

.

| molybdenum | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||