molybdenum electrode

Refractory molybdenum is a material used for specific electrodes and is

indispensable in industry. With their help, you can weld unexpected

combinations of metals and alloys with minimal consumption of electrode materials.

Using them, you can create the most uniform seams without the need for

further processing with abrasives. The possibility of defect formation is also

minimized, therefore, under certain technical conditions, no joint

inspection is required.

Molybdenum electrodes are also used for welding glass and basalt. Their

main feature is that the glass from the melt does not adhere to the

surface. At the "MetallKomplekt" company, you can buy molybdenum electrodes

manufactured in strict accordance with the GOST standard. When used

according to guaranteed technical specifications and application conditions, they can

provide reliable and predictable output results.

Metal welding electrode

All refractory metals are used to produce specific welding accessories

or consumables. Molybdenum electrodes are rarely used for these purposes

because

their tungsten analogues are more common. Some alloys cannot be welded

with W-type electrodes.

Glass melting electrode

In this process, the molybdenum electrode only serves as a thermal

conductor with an inert surface. With their help, they just need to pass

between two

glass products and then squeeze them firmly.

General advantages of molybdenum electrodes

Compared with other electrodes in their application fields, they have

many advantages:

Metals have high elasticity, so with their help, you can press on the

glass to form various seams. Molybdenum electrodes maintain their

strength when the

glass melts.

The unique thermal conductivity of molybdenum allows you to always keep

the device in a high degree of use. From the moment the welding machine

was

turned on, a few seconds had passed before the process began.

Weak thermal expansion. This way, you can create high-precision seams

with constant geometric parameters over the entire length.

With their help, you can weld various colors of glass, the molten glass

will become an aggressive environment. At the same time, the molybdenum

electrode

does not affect the transparency.

If necessary, this electrode is very suitable for machining.

.

.

;

.

molybdenum

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

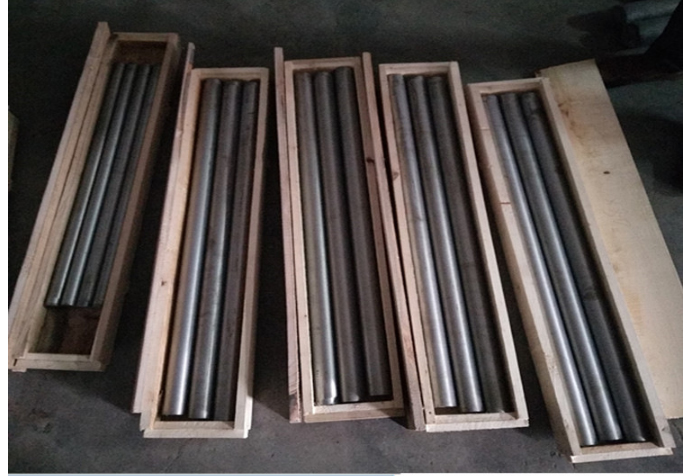

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

Refractory molybdenum is a material used for specific electrodes and is

indispensable in industry. With their help, you can weld unexpected

combinations of metals and alloys with minimal consumption of electrode materials.

Using them, you can create the most uniform seams without the need for

further processing with abrasives. The possibility of defect formation is also

minimized, therefore, under certain technical conditions, no joint

inspection is required.

Molybdenum electrodes are also used for welding glass and basalt. Their

main feature is that the glass from the melt does not adhere to the

surface. At the "MetallKomplekt" company, you can buy molybdenum electrodes

manufactured in strict accordance with the GOST standard. When used

according to guaranteed technical specifications and application conditions, they can

provide reliable and predictable output results.

Metal welding electrode

All refractory metals are used to produce specific welding accessories

or consumables. Molybdenum electrodes are rarely used for these purposes

because

their tungsten analogues are more common. Some alloys cannot be welded

with W-type electrodes.

Glass melting electrode

In this process, the molybdenum electrode only serves as a thermal

conductor with an inert surface. With their help, they just need to pass

between two

glass products and then squeeze them firmly.

General advantages of molybdenum electrodes

Compared with other electrodes in their application fields, they have

many advantages:

Metals have high elasticity, so with their help, you can press on the

glass to form various seams. Molybdenum electrodes maintain their

strength when the

glass melts.

The unique thermal conductivity of molybdenum allows you to always keep

the device in a high degree of use. From the moment the welding machine

was

turned on, a few seconds had passed before the process began.

Weak thermal expansion. This way, you can create high-precision seams

with constant geometric parameters over the entire length.

With their help, you can weld various colors of glass, the molten glass

will become an aggressive environment. At the same time, the molybdenum

electrode

does not affect the transparency.

If necessary, this electrode is very suitable for machining.

.

.

;

.

| molybdenum | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||