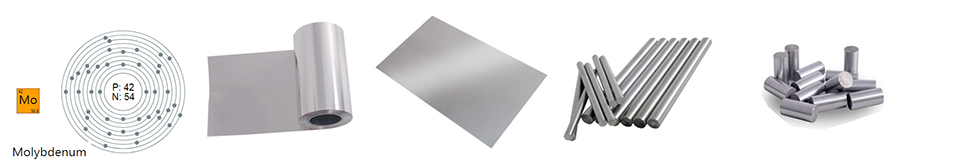

molybdenum sputtering target

Molybdenum is a shiny, silvery-white metal that occurs in the earth's

crust with a frequency of 1.5 ppm. It resembles tungsten in many ways,

with which it is often paired in the transition series of the periodic

table. The high-strength, tough and hard metal has a silvery-white

sheen. It has the highest melting point of all elements of the 5th

period.

A sputtering target is a high-purity material that is used for

sputtering.

Sputtering targets are used as the starting material for a wide variety

of coating processes, such as B. PVD, laser or ion beam technology

required.

Sputtering targets

We offer one of the largest and most extensive product lines of

sputtering targets. All common geometries (and sizes) are available.

Sputtering targets are used as the starting material for a wide variety

of coating processes, such as B. PVD, laser or ion beam technology

required.

Sputtering targets made from ceramic materials or from compositions that

cannot be produced by melting technology can be produced by powder

metallurgy by pressing powders or powder mixtures and subsequent

sintering or by hot pressing. The homogeneity, composition and purity of

the sputtering target can be set individually.

Sputtering target materials and quality

Our sputtering targets are available in a variety of compositions and in

different purity levels. All sputtering targets are checked for

composition, purity, density and finally for shape and dimensions in all

production stages. By using a wide variety of manufacturing processes

(e.g. powder metallurgy or melt metallurgy), each of which corresponds

to the latest state of the art, we can meet the highest quality

standards. Each production batch goes through different analysis

processes, which include can also be monitored by independent

laboratories.

Sputtering target bonding & backplate manufacturing

Depending on the system or material, your sputtering target must be

bonded. EVOCHEM uses both metallic and nano bond. Both methods enable a

secure and firm, electrically and thermally very conductive connection

between the target and the heat sink. We are also happy to bond your

sputtering targets to the back plates provided.

.

;

.

molybdenum

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

Molybdenum is a shiny, silvery-white metal that occurs in the earth's

crust with a frequency of 1.5 ppm. It resembles tungsten in many ways,

with which it is often paired in the transition series of the periodic

table. The high-strength, tough and hard metal has a silvery-white

sheen. It has the highest melting point of all elements of the 5th

period.

A sputtering target is a high-purity material that is used for

sputtering.

Sputtering targets are used as the starting material for a wide variety

of coating processes, such as B. PVD, laser or ion beam technology

required.

Sputtering targets

We offer one of the largest and most extensive product lines of

sputtering targets. All common geometries (and sizes) are available.

Sputtering targets are used as the starting material for a wide variety

of coating processes, such as B. PVD, laser or ion beam technology

required.

Sputtering targets made from ceramic materials or from compositions that

cannot be produced by melting technology can be produced by powder

metallurgy by pressing powders or powder mixtures and subsequent

sintering or by hot pressing. The homogeneity, composition and purity of

the sputtering target can be set individually.

Sputtering target materials and quality

Our sputtering targets are available in a variety of compositions and in

different purity levels. All sputtering targets are checked for

composition, purity, density and finally for shape and dimensions in all

production stages. By using a wide variety of manufacturing processes

(e.g. powder metallurgy or melt metallurgy), each of which corresponds

to the latest state of the art, we can meet the highest quality

standards. Each production batch goes through different analysis

processes, which include can also be monitored by independent

laboratories.

Sputtering target bonding & backplate manufacturing

Depending on the system or material, your sputtering target must be

bonded. EVOCHEM uses both metallic and nano bond. Both methods enable a

secure and firm, electrically and thermally very conductive connection

between the target and the heat sink. We are also happy to bond your

sputtering targets to the back plates provided.

.

;

.

| molybdenum | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||