Selenium

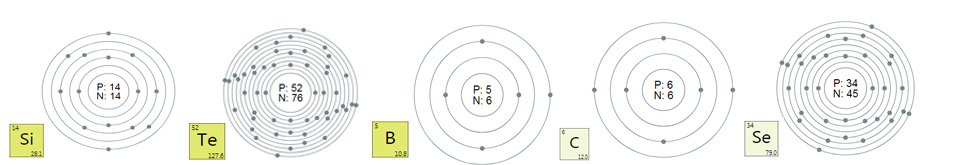

Selenium is a chemical element, its chemical symbol

is Se, and it is located in the VI A group of the fourth period in the

periodic table of chemical elements. It is a non-metal. It can be used

as photosensitive material, electrolytic manganese industry catalyst,

essential nutrient elements for animals and beneficial nutrient elements

for plants, etc. Selenium exists in nature in two ways: inorganic

selenium and plant active selenium. Inorganic selenium generally refers

to sodium selenite and sodium selenate, which are obtained from the

by-products of metal mineral deposits; the latter is a combination of

selenium through biotransformation and amino acids, generally in the

form of selenomethionine.

The main raw material (90%) for industrial extraction of selenium is the

anode slime produced by the electrolytic refining of copper, and the

rest comes from the calcine produced by the refining of lead, cobalt,

and nickel, and the residue from the production of sulfuric acid. Since

selenium in copper electrolysis anode slime is in the form of selenium

compound symbiosis with precious metals, the selenium content is about

5% to 25% (mass fraction). Therefore, the process is generally to

recover the precious metals gold and silver first, and then recover

selenium. A method of recovering selenium from anode slime to produce

gold and silver alloys.

There are three main types of anode slime treatment processes at home

and abroad: One is the full wet process. The main processes are: copper

anode slime-pressure leaching of copper, tellurium-chloride leaching of

selenium, gold-alkaline leaching, lead-ammonia leaching,

silver-gold-silver electrolysis; the second is mainly wet method, fire

method and wet method The combined semi-wet process is adopted by most

domestic manufacturers. The main process is: copper anode slime-sulfuration

roasting, steaming selenium, dilute acid, copper-chloride, gold-sodium

sulfite, silver-gold and silver electrolysis; the third is the fire

method, which is based on the fire method, and combines the wet method

and the fire method. The main process is: copper anode slime-pressure

leaching of copper, tellurium-fire method smelting, blowing-silver

electrolysis-silver anode slime to process gold.

There are two main methods for industrial production of selenium: one is

oxidizing and roasting anode slime and SeO2 distillation. The process is

to capture gaseous SeO2 roasting gas in a scrubber with a solution, and

then precipitate it in an acid medium or lye under the action of SO2.

Selenium; the other is to add soda ash to sinter the anode slime in an

oxidizing atmosphere to convert selenium into sodium selenide or sodium

selenate water-soluble solution. The process is to oxidize selenium and

selenide to easily soluble in water under sintering conditions. Sodium

selenate or sodium selenate, and then purging to separate selenium from

the solution.

.

.

Selenium is a chemical element, its chemical symbol

is Se, and it is located in the VI A group of the fourth period in the

periodic table of chemical elements. It is a non-metal. It can be used

as photosensitive material, electrolytic manganese industry catalyst,

essential nutrient elements for animals and beneficial nutrient elements

for plants, etc. Selenium exists in nature in two ways: inorganic

selenium and plant active selenium. Inorganic selenium generally refers

to sodium selenite and sodium selenate, which are obtained from the

by-products of metal mineral deposits; the latter is a combination of

selenium through biotransformation and amino acids, generally in the

form of selenomethionine.

The main raw material (90%) for industrial extraction of selenium is the

anode slime produced by the electrolytic refining of copper, and the

rest comes from the calcine produced by the refining of lead, cobalt,

and nickel, and the residue from the production of sulfuric acid. Since

selenium in copper electrolysis anode slime is in the form of selenium

compound symbiosis with precious metals, the selenium content is about

5% to 25% (mass fraction). Therefore, the process is generally to

recover the precious metals gold and silver first, and then recover

selenium. A method of recovering selenium from anode slime to produce

gold and silver alloys.

There are three main types of anode slime treatment processes at home

and abroad: One is the full wet process. The main processes are: copper

anode slime-pressure leaching of copper, tellurium-chloride leaching of

selenium, gold-alkaline leaching, lead-ammonia leaching,

silver-gold-silver electrolysis; the second is mainly wet method, fire

method and wet method The combined semi-wet process is adopted by most

domestic manufacturers. The main process is: copper anode slime-sulfuration

roasting, steaming selenium, dilute acid, copper-chloride, gold-sodium

sulfite, silver-gold and silver electrolysis; the third is the fire

method, which is based on the fire method, and combines the wet method

and the fire method. The main process is: copper anode slime-pressure

leaching of copper, tellurium-fire method smelting, blowing-silver

electrolysis-silver anode slime to process gold.

There are two main methods for industrial production of selenium: one is

oxidizing and roasting anode slime and SeO2 distillation. The process is

to capture gaseous SeO2 roasting gas in a scrubber with a solution, and

then precipitate it in an acid medium or lye under the action of SO2.

Selenium; the other is to add soda ash to sinter the anode slime in an

oxidizing atmosphere to convert selenium into sodium selenide or sodium

selenate water-soluble solution. The process is to oxidize selenium and

selenide to easily soluble in water under sintering conditions. Sodium

selenate or sodium selenate, and then purging to separate selenium from

the solution.

.

.

|

|