Tungsten Stab

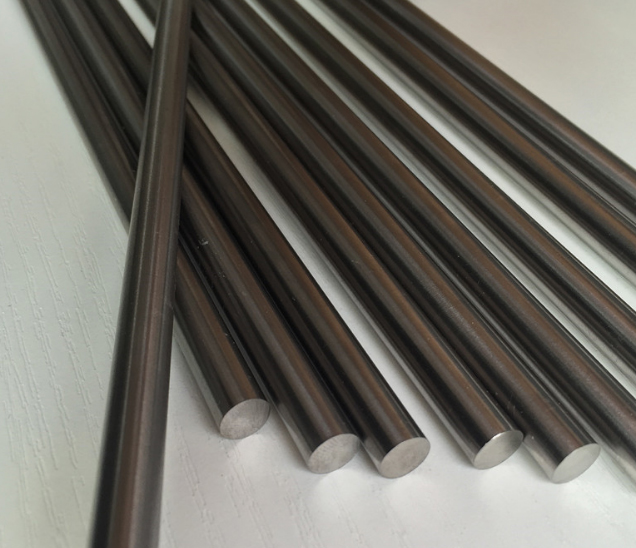

Tungsten rods and their features

Tungsten rods are blanks that, in cross section, are a circle, square,

rectangle, hexagon, trapezoid, segment or oval. The product is a

semi-finished product, and is used to obtain various parts.

Production

A rotary machine is used to make tungsten rods. Method of production -

forging from pre-heated to 1500 ° C bacon. The length of the process

depends on what diameter the product should be. During the first stage,

the thickness of the tungsten rod is from 7 to 8 mm. Such a production

technology increases the wear resistance of the material, for example,

the contact made from a cut perpendicular to the forging direction of a

given high-grade metal will be more resistant to wear than a rolling

plate.

Advantages and disadvantages

Tungsten rods differ in a number of advantages:

high working temperature;

strength and hardness regardless of the aggressiveness of the

environment;

high ohmic resistance;

significant modulus of elasticity;

creep resistance when exposed to high temperatures.

The disadvantages of tungsten rods include the high density of the

metal, which significantly affects the weight of the workpiece, as well

as brittleness at room temperature. It requires special storage and

transportation conditions.

Both in injection molding and in the field of device technology and

machine processing and in the lighting industry: our rods made of

molybdenum and its alloys are characterized by the highest material

purity and consistently high quality.

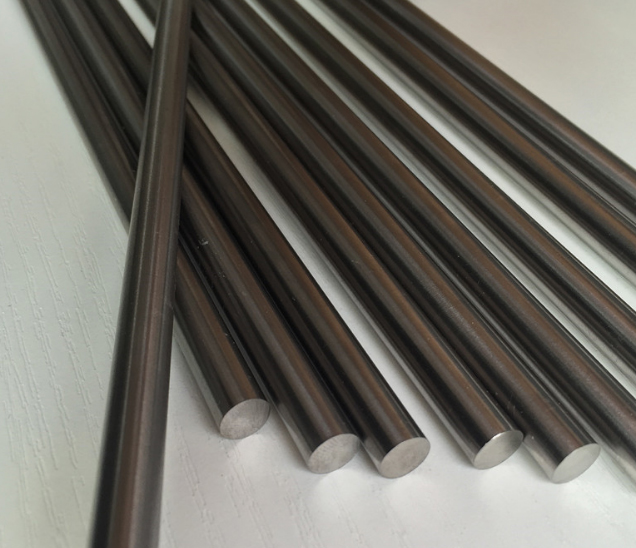

We pay particular attention to absolute accuracy in the production of

tungsten rods. We try to reduce tolerances, both in diameter and

roundness, which guarantees the rods exceptional straightness. Our

innovative equipment and many years of experience in the field of

refractory metals allows us to manufacture tungsten rods with a diameter

of up to 100 mm.

We manufacture our tungsten rods from highly pure micro-granular

materials that guarantee good machining ability. We conduct ultrasonic

or eddy current testing of each rod. Our range includes different

quality coatings: smooth, non-centered, forged, etched. Share your

wishes with us!

The second after the tungsten wire in frequency of use is rightly

considered a tungsten bar. It is rarely produced from pure metal,

because in combination with other substances it exhibits completely

different properties. The only thing that is precisely inherited from

the core material of the bar is the unprecedented refractoriness and

thermal stability, which predetermines its use in high-temperature

systems.

.

Tungsten

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

Tungsten rods and their features

Tungsten rods are blanks that, in cross section, are a circle, square,

rectangle, hexagon, trapezoid, segment or oval. The product is a

semi-finished product, and is used to obtain various parts.

Production

A rotary machine is used to make tungsten rods. Method of production -

forging from pre-heated to 1500 ° C bacon. The length of the process

depends on what diameter the product should be. During the first stage,

the thickness of the tungsten rod is from 7 to 8 mm. Such a production

technology increases the wear resistance of the material, for example,

the contact made from a cut perpendicular to the forging direction of a

given high-grade metal will be more resistant to wear than a rolling

plate.

Advantages and disadvantages

Tungsten rods differ in a number of advantages:

high working temperature;

strength and hardness regardless of the aggressiveness of the

environment;

high ohmic resistance;

significant modulus of elasticity;

creep resistance when exposed to high temperatures.

The disadvantages of tungsten rods include the high density of the

metal, which significantly affects the weight of the workpiece, as well

as brittleness at room temperature. It requires special storage and

transportation conditions.

Both in injection molding and in the field of device technology and

machine processing and in the lighting industry: our rods made of

molybdenum and its alloys are characterized by the highest material

purity and consistently high quality.

We pay particular attention to absolute accuracy in the production of

tungsten rods. We try to reduce tolerances, both in diameter and

roundness, which guarantees the rods exceptional straightness. Our

innovative equipment and many years of experience in the field of

refractory metals allows us to manufacture tungsten rods with a diameter

of up to 100 mm.

We manufacture our tungsten rods from highly pure micro-granular

materials that guarantee good machining ability. We conduct ultrasonic

or eddy current testing of each rod. Our range includes different

quality coatings: smooth, non-centered, forged, etched. Share your

wishes with us!

The second after the tungsten wire in frequency of use is rightly

considered a tungsten bar. It is rarely produced from pure metal,

because in combination with other substances it exhibits completely

different properties. The only thing that is precisely inherited from

the core material of the bar is the unprecedented refractoriness and

thermal stability, which predetermines its use in high-temperature

systems.

.

| Tungsten | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||