Tungsten electrode

An electrode is a rod based on an electrically conductive material for

supplying current to a welded product (pipe, sheet, corner, square.

Currently, there are more than 100 brands of electrodes in Ukraine, and

more than half of the electrodes produced are melting for manual arc

welding. two types of welding are argon and arc.

A tungsten electrode is one of the most effective electrodes since

tungsten is the most refractory metal present on earth, its melting

point is 3410 ° С, boiling point is 10220 ° С, density is 19.3 g / cm^3.

Hardness is maintained even when the temperature reaches 400-500 ° C.

The consumption of tungsten during welding is very small - hundredths of

a gram per 1 meter of the weld, and tungsten electrodes alloyed with

oxides and rare-earth elements are even more resistant!

At this time, tungsten electrodes have a diverse chemical composition

with different properties. To achieve higher characteristics during

welding, various oxides of various rare-earth metals are introduced into

tungsten, such as: lanthanum, yttrium, cerium, zirconium and thorium.

Refractory tungsten electrodes are used exclusively for welding metal in

an inert atmosphere. This is the only way to weld austenitic steel by

portable welding outside the conditions of a special chamber. The low

fusion coefficient of these electrodes allows you to weld very thin

parts, up to the thickness of the foil. Another area of application is

the welding of refractory alloys, when the thermal stability of the

electrode should be extremely high.

Due to its refractoriness, tungsten electrodes provide an extremely low

material consumption per 1 meter of seam. To carry out such an

operation, it is necessary to spend milligrams of metal. Those who

believe that buying tungsten electrodes means harming themselves are

mistaken. Despite the high cost, they pay off with this expense. In

addition, they can significantly reduce working time to perform tasks of

large volume. They demonstrate high thermal stability, due to which it

is possible to precisely comply with the welding process with a minimum

percentage of rejects.

Products are manufactured at partner enterprises, therefore tungsten

electrodes are available to our customers at a low price. MetalKomplekt

guarantees strict compliance with GOST and ISO standards. In production,

total quality control is used at each stage, so the marriage is

excluded.

The difference between a conventional electrode and a tungsten

Compared with argon arc welding, the quality of the seam with the

tungsten electrode is much higher, it turns out to be almost continuous.

Despite the high cost of the tungsten electrode, it is much more

profitable due to the low consumption of material.

What determines the cost

The price of a tungsten electrode directly depends on the amount of

metal that went into its manufacture..

.

Tungsten

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

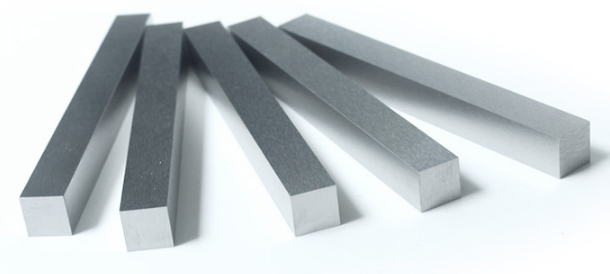

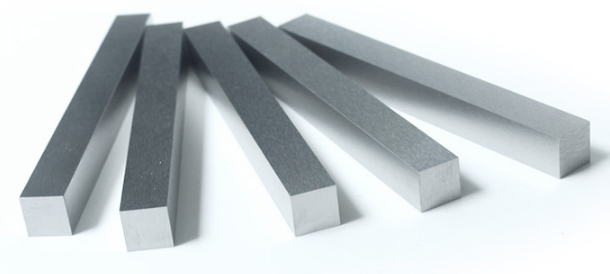

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

An electrode is a rod based on an electrically conductive material for

supplying current to a welded product (pipe, sheet, corner, square.

Currently, there are more than 100 brands of electrodes in Ukraine, and

more than half of the electrodes produced are melting for manual arc

welding. two types of welding are argon and arc.

A tungsten electrode is one of the most effective electrodes since

tungsten is the most refractory metal present on earth, its melting

point is 3410 ° С, boiling point is 10220 ° С, density is 19.3 g / cm^3.

Hardness is maintained even when the temperature reaches 400-500 ° C.

The consumption of tungsten during welding is very small - hundredths of

a gram per 1 meter of the weld, and tungsten electrodes alloyed with

oxides and rare-earth elements are even more resistant!

At this time, tungsten electrodes have a diverse chemical composition

with different properties. To achieve higher characteristics during

welding, various oxides of various rare-earth metals are introduced into

tungsten, such as: lanthanum, yttrium, cerium, zirconium and thorium.

Refractory tungsten electrodes are used exclusively for welding metal in

an inert atmosphere. This is the only way to weld austenitic steel by

portable welding outside the conditions of a special chamber. The low

fusion coefficient of these electrodes allows you to weld very thin

parts, up to the thickness of the foil. Another area of application is

the welding of refractory alloys, when the thermal stability of the

electrode should be extremely high.

Due to its refractoriness, tungsten electrodes provide an extremely low

material consumption per 1 meter of seam. To carry out such an

operation, it is necessary to spend milligrams of metal. Those who

believe that buying tungsten electrodes means harming themselves are

mistaken. Despite the high cost, they pay off with this expense. In

addition, they can significantly reduce working time to perform tasks of

large volume. They demonstrate high thermal stability, due to which it

is possible to precisely comply with the welding process with a minimum

percentage of rejects.

Products are manufactured at partner enterprises, therefore tungsten

electrodes are available to our customers at a low price. MetalKomplekt

guarantees strict compliance with GOST and ISO standards. In production,

total quality control is used at each stage, so the marriage is

excluded.

The difference between a conventional electrode and a tungsten

Compared with argon arc welding, the quality of the seam with the

tungsten electrode is much higher, it turns out to be almost continuous.

Despite the high cost of the tungsten electrode, it is much more

profitable due to the low consumption of material.

What determines the cost

The price of a tungsten electrode directly depends on the amount of

metal that went into its manufacture..

.

| Tungsten | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||