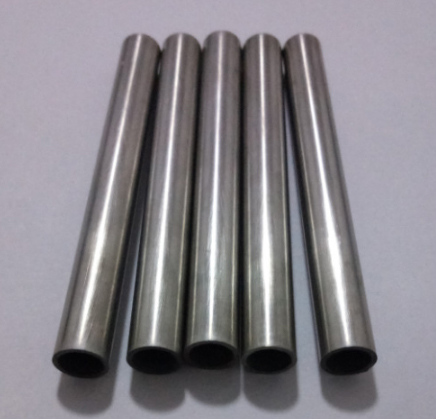

Tungsten Pipe

tungsten pipe

The advantage of a tungsten pipe is manifested in the refractoriness of

tungsten, its heat resistance and heat resistance. Pipes are resistant

to many aggressive environments, including solutions of alkali,

sulfuric, hydrochloric and nitric acids. Tungsten products have many

distinctive qualities: wear resistance and protection against fatigue

during heating and cooling and the lowest coefficient of expansion among

metals of this class. Tungsten has a wide range of tension and

compression, good resistance to thermal creep and high thermal

conductivity. The complex technological process for producing tungsten

leads to an increase in the total cost of tungsten products. Moreover,

the weight of finished products is very high.

They produce tungsten pipes from billets using high-tech equipment.

Using vacuum heat treatment and modern chemical processing technologies.

The quality of the material produced is monitored at all stages.

.

Tungsten

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

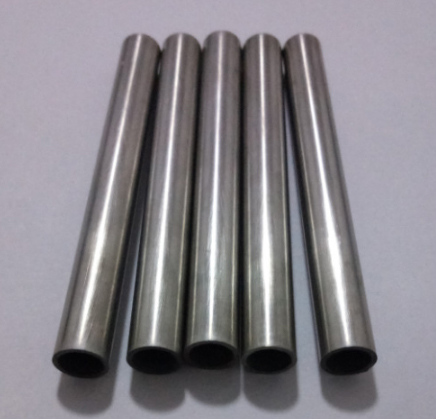

tungsten pipe

The advantage of a tungsten pipe is manifested in the refractoriness of

tungsten, its heat resistance and heat resistance. Pipes are resistant

to many aggressive environments, including solutions of alkali,

sulfuric, hydrochloric and nitric acids. Tungsten products have many

distinctive qualities: wear resistance and protection against fatigue

during heating and cooling and the lowest coefficient of expansion among

metals of this class. Tungsten has a wide range of tension and

compression, good resistance to thermal creep and high thermal

conductivity. The complex technological process for producing tungsten

leads to an increase in the total cost of tungsten products. Moreover,

the weight of finished products is very high.

They produce tungsten pipes from billets using high-tech equipment.

Using vacuum heat treatment and modern chemical processing technologies.

The quality of the material produced is monitored at all stages.

.

| Tungsten | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||