Pure niobium Wire

Niobium wire, as well as the thread is made by cold drawing, i.e. This

operation is performed without heating the semi-finished products.

However, intermediate recrystallization annealing is performed between

the passages. The starting material for its production is forged or

pressed blanks in the form of rods. Preliminary hot deformation is

performed in order to reduce the size of the workpieces, as well as to

give the material the necessary ductility. The temperature at which this

process is performed is about 1100-1500 ° C. Before drawing, the

semi-finished products are coated with grease, which is used as a

colloidal-graphite mixture.

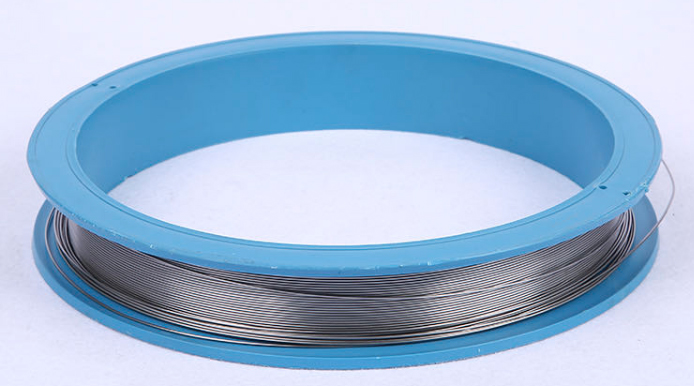

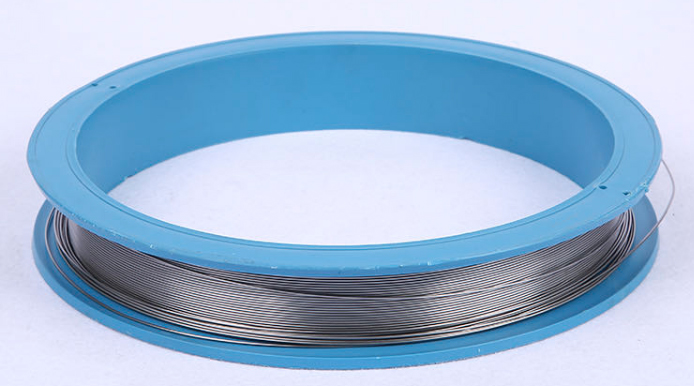

Finished products are supplied chartered. The diameters of the products

are 0.4-0.8 mm.

Application

The main purpose of niobium wire is the production of

oxide-semiconductor capacitors used in the electronic industry. This

application is similar to tantalum products. Another traditional use of

niobium wire is the production of superconductors. They are actively

used in high-tech industries, for example, in nuclear physics, nuclear

energy.

Niobium wire is obtained by drawing from pressed or forged niobium

billets of the corresponding grades.

Niobium wire is characterized by high strength and corrosion resistance,

heat resistance and wear resistance, electrical conductivity and

ductility.

Niobium wire is able to withstand temperatures above 1500 degrees, can

be easily processed, both hot and cold methods, resistant to aggressive

environments.

Niobium wire is widely used in:

aviation

Automotive

chemical

jewelry industries,

astronautics,

medicine

radio engineering

electrical engineering

nuclear power

the production of superconductors, etc.

Niobium wire

The diameter of the product may be in the range of 0.15-6 mm.

Any cracks on the surface are completely absent, and on the kink -

foreign inclusions are unacceptable.

It is delivered in coils or bays (depending on the diameter of the

product).

It is stored in a dry, protected from moisture, possible ingress of dirt

or mechanical damage, the room.

.

Niobium

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

Niobium wire, as well as the thread is made by cold drawing, i.e. This

operation is performed without heating the semi-finished products.

However, intermediate recrystallization annealing is performed between

the passages. The starting material for its production is forged or

pressed blanks in the form of rods. Preliminary hot deformation is

performed in order to reduce the size of the workpieces, as well as to

give the material the necessary ductility. The temperature at which this

process is performed is about 1100-1500 ° C. Before drawing, the

semi-finished products are coated with grease, which is used as a

colloidal-graphite mixture.

Finished products are supplied chartered. The diameters of the products

are 0.4-0.8 mm.

Application

The main purpose of niobium wire is the production of

oxide-semiconductor capacitors used in the electronic industry. This

application is similar to tantalum products. Another traditional use of

niobium wire is the production of superconductors. They are actively

used in high-tech industries, for example, in nuclear physics, nuclear

energy.

Niobium wire is obtained by drawing from pressed or forged niobium

billets of the corresponding grades.

Niobium wire is characterized by high strength and corrosion resistance,

heat resistance and wear resistance, electrical conductivity and

ductility.

Niobium wire is able to withstand temperatures above 1500 degrees, can

be easily processed, both hot and cold methods, resistant to aggressive

environments.

Niobium wire is widely used in:

aviation

Automotive

chemical

jewelry industries,

astronautics,

medicine

radio engineering

electrical engineering

nuclear power

the production of superconductors, etc.

Niobium wire

The diameter of the product may be in the range of 0.15-6 mm.

Any cracks on the surface are completely absent, and on the kink -

foreign inclusions are unacceptable.

It is delivered in coils or bays (depending on the diameter of the

product).

It is stored in a dry, protected from moisture, possible ingress of dirt

or mechanical damage, the room.

.

| Niobium | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||